NO DIG UV LINING DRAINAGE REPAIRS

- 70 Year Guarantee

- WRC Approved

- Environmentally Friendly

NO COMPROMISE ON SEWER PIPE REHABILITATION

Traditional methods of drainage pipe replacement under roads or properties would normally budget a huge cost, have higher safety risks and be programmed out for a long period of time. Drainforce can reduce costs by a considerable amount and increase productivity, whilst most importantly eliminating the safety risks on the network associated with traditional dig down pipe replacement methods.

Our methods of UV lining can create a far safer environment for workers while increasing productivity and reducing costs and environmental impact.

We can UV line different from 100mm up to 2000mm with wall thicknesses from 3mm up to 30mm. Drainforce are WRC approved installers of Saertex Liners. We offer complete consultancy and design for every job.

- Line diameters from 150mm to 2000mm

- Single lengths of up to 300m

- Main line rigs and portable systems for difficult access

- Turn key solutions from CCTV through to design and installation

UV Lining FAQs

Read our frequently asked questions for the answers to common questions about UV lining below:

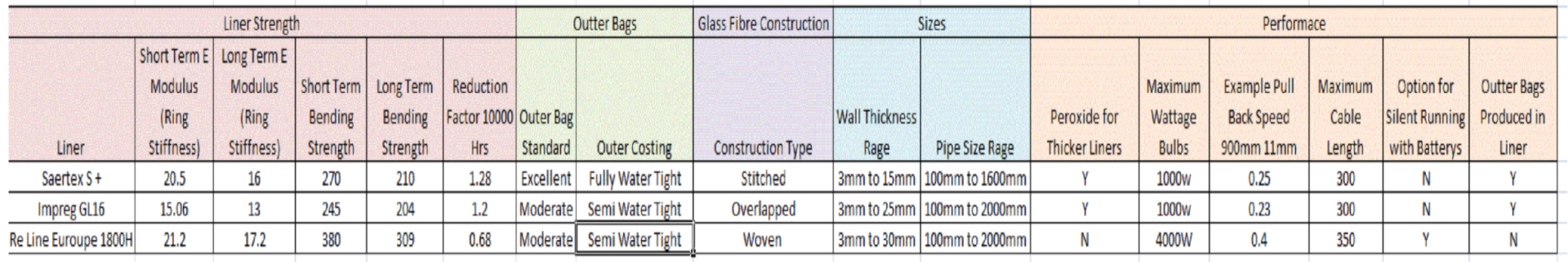

UV Lining Product Comparison

Drainforce offer 3 Wrc approved installation Certificates for 3 Liner Wrc approved manufacturers. (Saertex, Impreg and Re Liner Europe) Each Liner is constructed differently which in turn offers specific advantages. This presentation compares the characteristics of each liner and how this benefits the asset owner in different situations on site.

SAERTEX multicom

- Higher Strength Liner than many competitors.

- Heavy Duty Outer Bagging.

- Watertight Outer Bag.

- Glass Fibre is stitched construction.

- Option to have premium Liner with no inner bag.

Advantages

- Excellent for Infiltration with water tight outer protection

- Excellent for lining High Service Defective pipes with Free in air liner option with Built in safety cap at factory

- Better for smaller circular pipes due to construction of

- Circumference Change can be built into liner.

- Faster Process with no inner bag to pull out and Less Risk on Network.

Disadvantages

- Liner Thickness only to 15mm.

- Peroxides in Thickness Above 11mm.

- Unable to cure with Higher Wattage Bulbs.

- Unforgiving in Non Circular or within Pipes with Slight variance in circumference.

IMPREG Group

- Manufactured with overlapped sheets of Glass Fibre.

- Can produce up to 25mm thick liners.

- Can produce 2000mm diameter Liners.

- Can be produced with Built in Jeans for Free in Air lining.

- Can be produced with Addition Protection on outer bag.

Advantages

- Excellent for larger pipes and Non Circular due to construction being overlapped.

- Excellent for lining High Service Defective pipes with Free in air liner option with Built in safety cap at factory.

- Circumference Change can be built into liner.

- Folds can be produced in the liner for variances in circumference.

- UK Assistance with Local Technician to Thames area.

- UK Stores for stock holding.

Disadvantages

- Can over stretch liner due to construction without built in Jeans.

- Slight variances in Ovality due to construction.

- Peroxides in Thickness Above 11mm.

- Unable to cure with Higher Wattage Bulbs.

- Not suitable for Infiltration as standard.

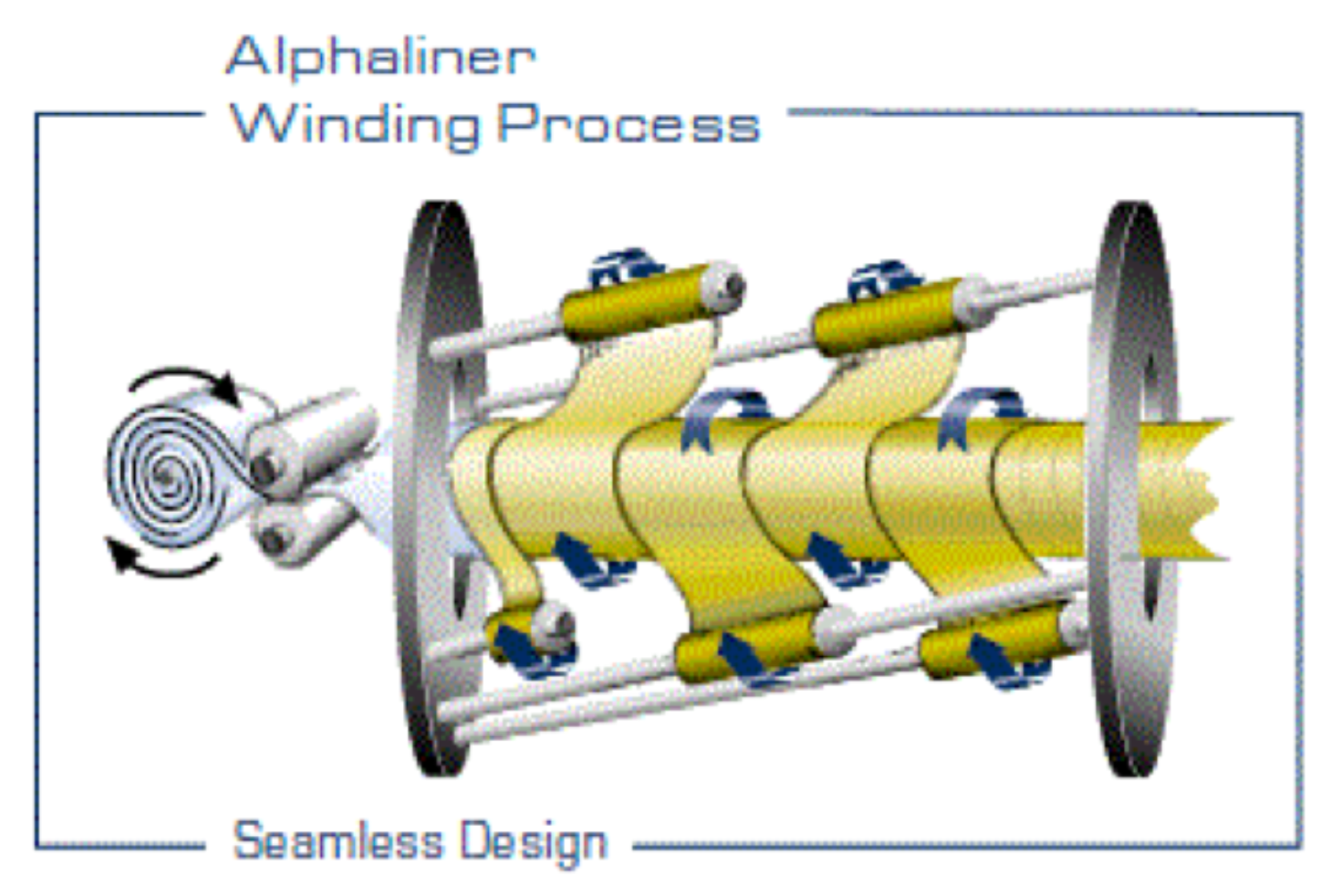

RELINE UV

- Excellent for larger pipes and Non-Circular due to construction being overlapped.

- Lightest Liner on the Market due to construction being woven.

- Equal Thickness Strongest Liner on the Market.

- Round liner.

- Can Produce 2000mm Diameter Liners.

- Can Produce thickness up to 30mm.

Advantages

- Faster Curing with upto 4000w bulbs.

- No Requirement for Peroxide and there for no Risk of Liner going off (Longer Storage Life)

- Thinker and Lighter Liners there for Thinner designs and less equipment required to Winch in.

Disadvantages

- Unable to cure Liner with any other Rigs other than their Own.

- Not suitable for Infiltration as standard.

- Unable to Produce built in Jeans for Free in Air Lining, this has to be completed on site with Pre Liner.

Summary

- By being involved at Gate 1 we can offer suitable solutions in collaboration with Thames

- Offer greater Flexibility

- Less Disruption to Customers

- Offer Longer Storage times of Liners

- Offer faster Order times of Products

- Wrc approved product

- Wrc approved installers

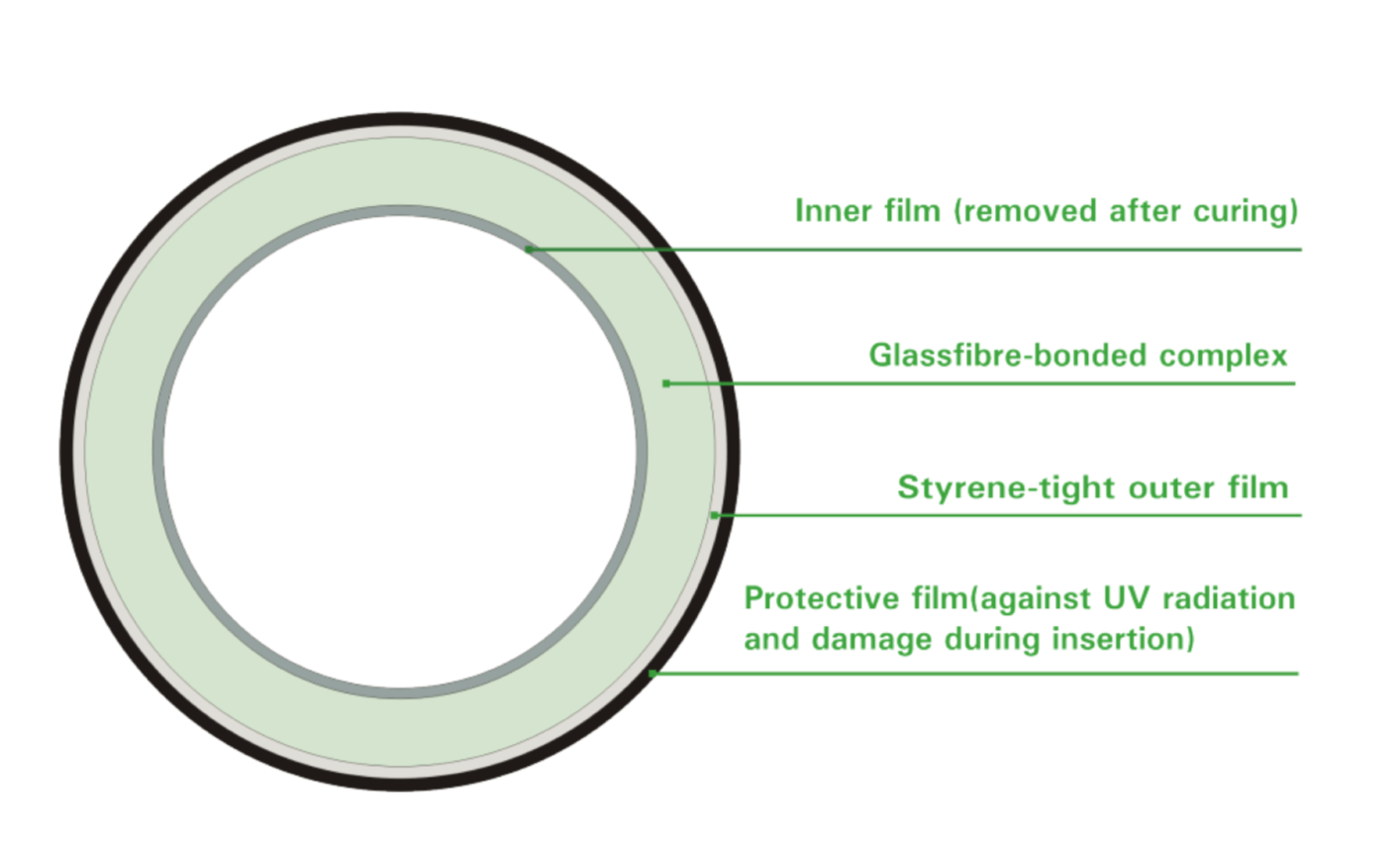

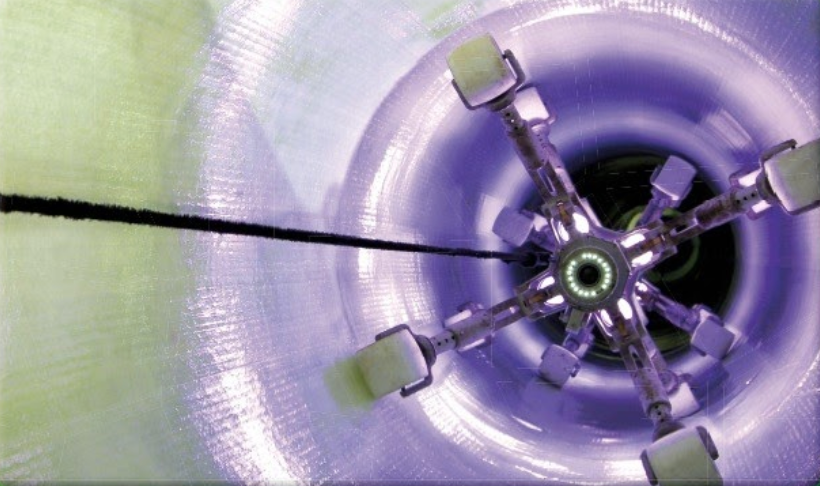

SAERTEX-LINER: Installation Process

- Calibration of the SAERTEX-LINER® using compressed air

- Insertion of the light source

- Curing as detailed in the installation instruction

- Removal of the packers at the liner ends in the manhole

- Removal of inner film and afterwards leakage test (not necessary for the SAERTEX-LINER® Premium)

- Opening of side inletes and thus fast recommissioning of line and sewerage network