MANHOLE & ASSET SURVEYS

- STC25 manhole card trained engineers

- High risk confined space trained engineers

- Topcon GPS surveying/mapping

- Drainage asset surveys

GPS SURVEYING & HIGH QUALITY REPORTS

- 26-32t dirty water Kaiser Whale recycler

- Off road remote reels for difficult access locations

- 120 gallons per minutes at 2000psi

- 300m of jetting hose on the trucks alone

- Confined space rescue engineers

- Pumping station survey

MANHOLE REHABILITATIons

aManholes on Sewer and Drainage Networks are fixed structures that allow access into the Network for service and maintenance works of the Networks. Manholes are at Risk of service and structural defects in the same way the network is.

Example Problems

- Hydrogen Sulphide (H2S) Can cause surface Spalding to concrete and structural damage to the Manhole structures if not dealt with.

- Infiltration from Ground water around the Manhole

- Exfiltration of Sewage into Water Ways

- Structural defects such as cracks and fractures.

- Drainforce can provide innovative solutions for the repair and maintenance of manholes and chambers by the following techniques.

OUR SOLUTION

Drainforce can provide innovative solutions for the repair and maintenance of manholes and chambers by the following techniques.

M Coating my Hermes

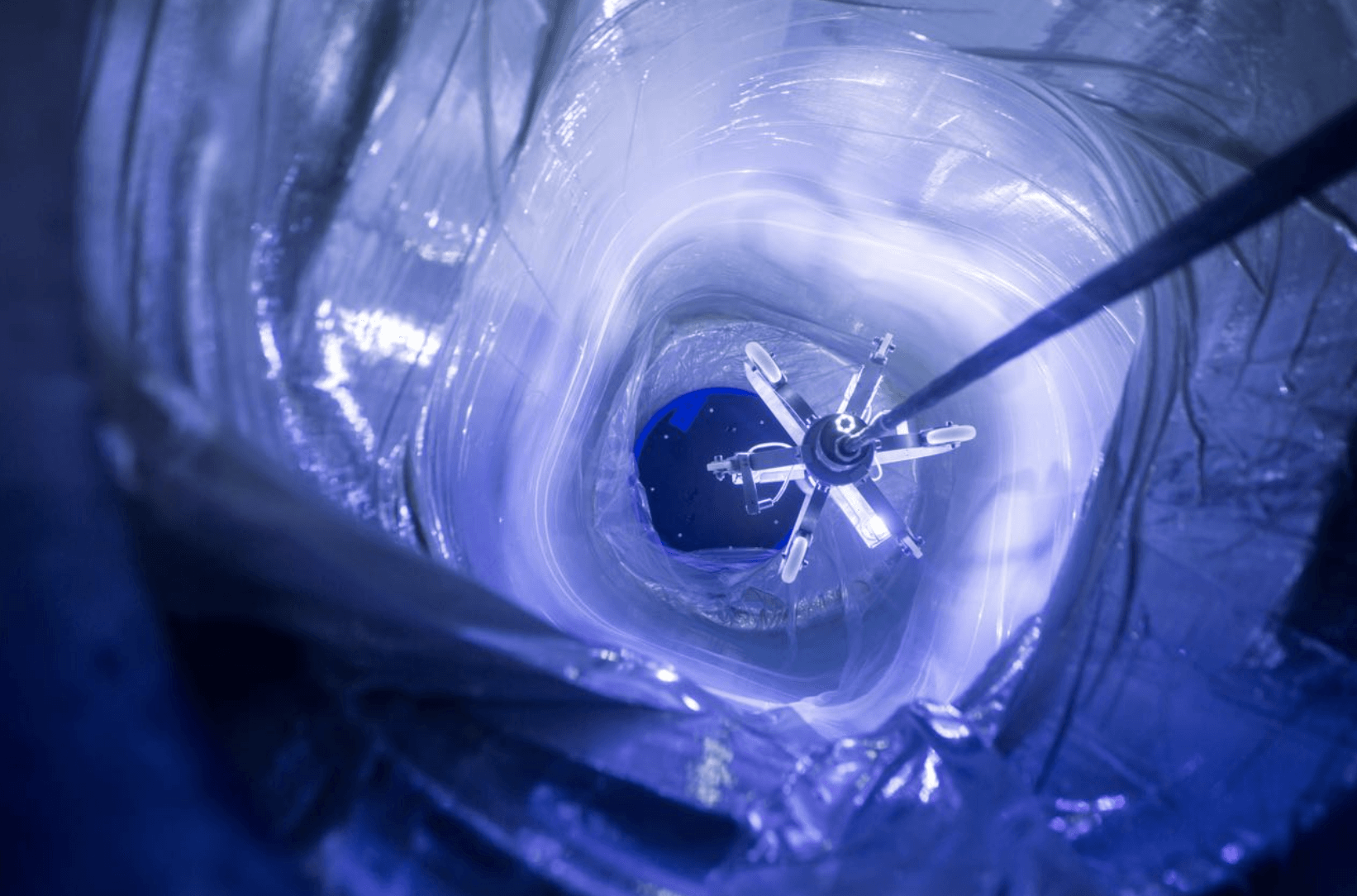

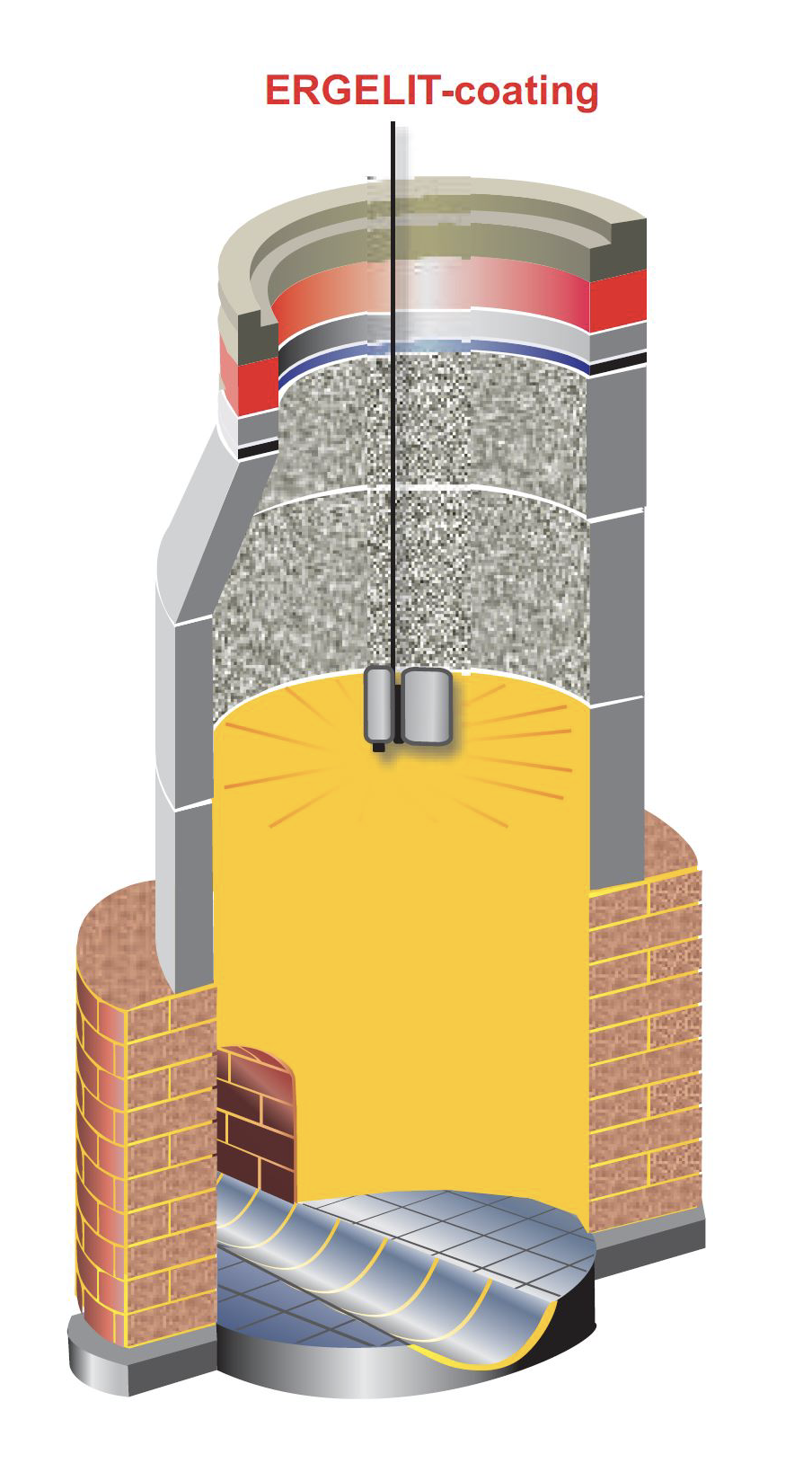

The M Coating can be used on any shape structure ranging from 500mm to 1200m The system works by using a centrifuge spray technique. Wall shafts of upto 10 metres deep can be coated . The system is an automatic system where no human entry is required into the shaft making the operation safe and efficient.

- Cleaning. The first operation is the cleaning of the Manhole using the TSS fully automated cleaning machine which turn though a 360 degree angle with pressures upto 350bar.

- The Coating. The coating process is based on an integrated system consisting of a mixer, a pump and a centrifugal spray. All three components are fully automated. For loading the grout or controlling the mixer and pump, only one operator is needed. The centrifugal spray attached to the gantrymounted winch is guided up and down the shaft at constant speed by a second operator

Quality Assurance

The M-COATING automated system removes many of the sources of error in substrate preparation and the subsequent coating process. It also offers user-friendly operation and an improved level of safety. A quality assurance handbook provides the operator with a guide to the very best renovation practice, and the client with additional reassurance thanks to a quality assurance certificate issued for every shaft . renovated by the M-COATING process. M-COATING is tested by M-COATING TSSR is tested by M-Coating has achieved DIBt certificate n?Z-53.5-461 „Coating mortar ERGELIT-KS1 and injection mortar ERGELIT-KBi for the rehabilitation of wastewater collection systems and inspection shafts, using the M-Coating process.“ Request references, certificates, site reports or videos. We currently have a large amount of information about renovation available for your use, at www.hermes-technolgie.de ERGELIT-KS is independently inspected by the MPA NRW. These ERGELIT-mortars meet the specifications set out in GSTT Information Sheet nº 18 and DWA M 143-17. TECHNOLOGIE HERMES Ltd. Q